Revolutionize Your Production with TITAN Catalytic Ovens

Our catalytic ovens utilize cutting-edge catalytic heating technology, which offers several advantages over traditional convection ovens. From faster heating times to more uniform heat distribution, our ovens are designed to optimize your production efficiency and quality.

Key Features:

- Faster Heating Times: Our catalytic ovens offer rapid heating, reducing production cycle times and increasing throughput.

- Precise Temperature Control: With advanced temperature control features, you can ensure consistency and quality in your heating processes.

- Energy-Saving Design: Our ovens are engineered for energy efficiency, helping you reduce operating costs and minimize environmental impact.

- Versatile Applications: Whether you’re curing coatings, drying materials, or performing heat treatment processes, our catalytic ovens are suitable for a wide range of applications.

Product Details

Construction Options

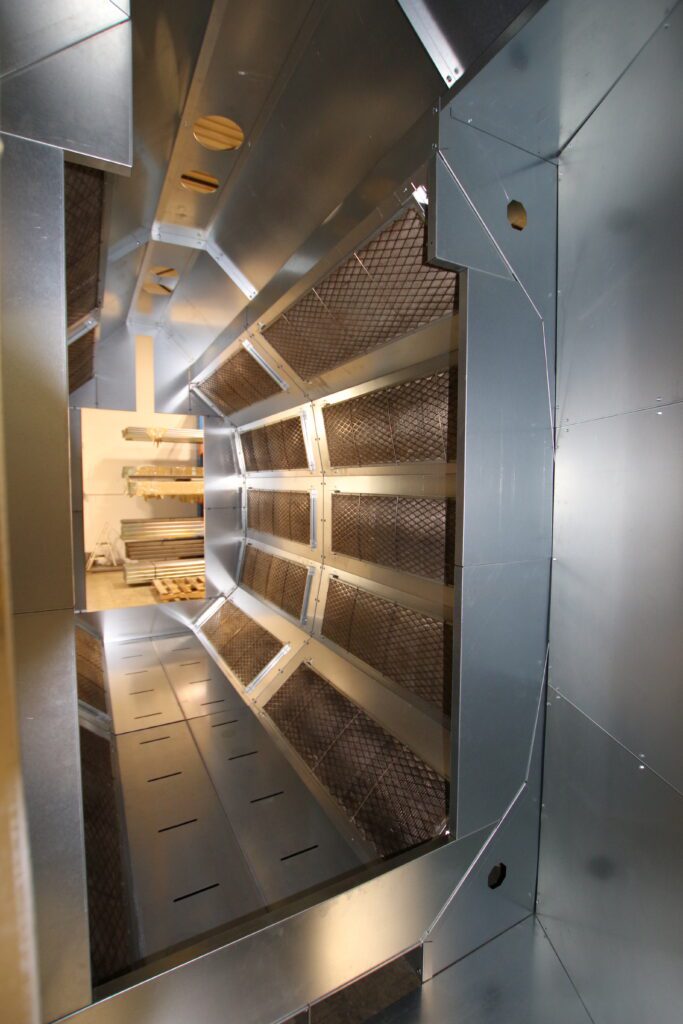

Gas Catalytic IR ovens from TITAN can be supplied in two ways: Fully assembled (pre-wired and plumbed) individual sections, quick to assemble and commission. Kit systems are available for customers with in-house sheet metal fabrication. TITAN will provide DXF part files of the proven oven design, along with the heaters, controls, gas management system and provide all the back-up support the customer needs to build their oven in-house.

Benefits of Gas Catalytic Heating

We are proud to offer the latest in long-wave to medium-wave infrared heating technology. Our Gas Catalytic IR heaters provide a unique and powerful solution for customers looking for better control over their heating systems. Adopting Gas Catalytic IR technology into your production process will:

reduction in cure time

reduction in overall costs

or more reduction in footprint

Ask us about our free testing service!

We offer a free parts testing service at our plant in Bristol, Connecticut. You may schedule an appointment in person or mail your parts to us and we will return them for your inspection.