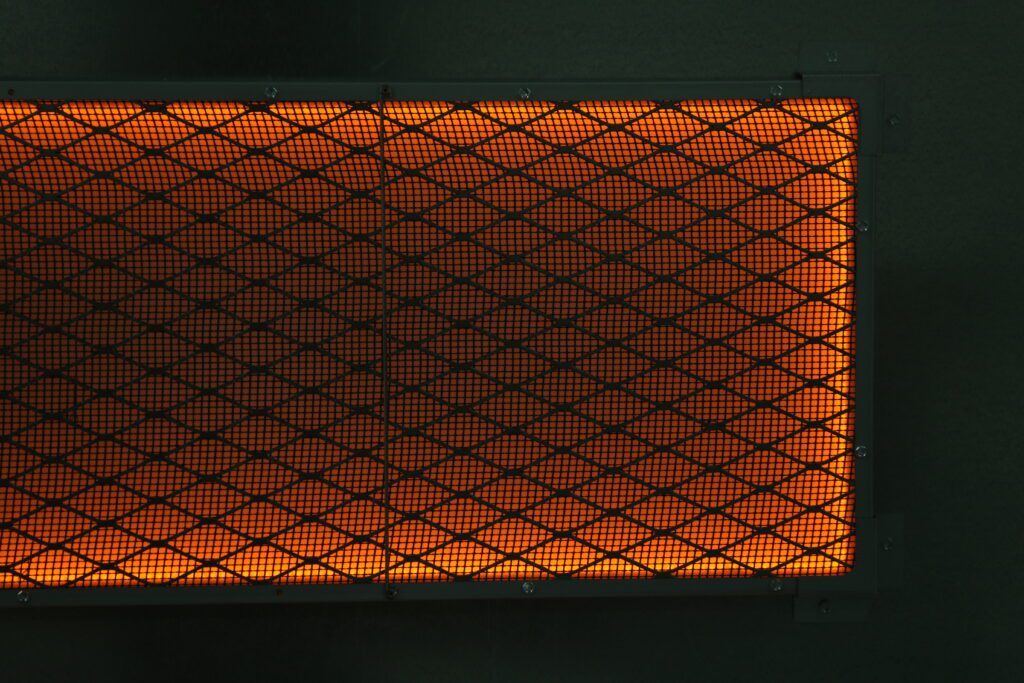

Gas Catalytic Heaters

The Future of Heating: Catalytic Infrared

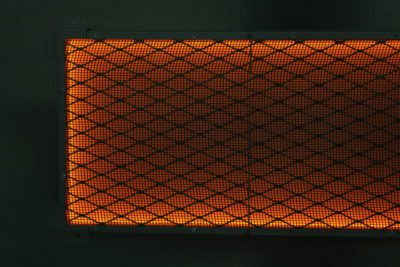

Catalytic heating has gained popularity recently for its energy efficiency and cost-effectiveness compared to traditional convection heat systems. Catalytic heating utilizes a catalytic converter to transform natural gas or propane into heat through oxidation. This generated heat is then evenly distributed throughout the building or home. Unlike traditional heating methods that burn fuel to produce heat, catalytic heating is more efficient. By investing in a TITAN-Catalytic Gas IR heater, you can save space, reduce energy costs, and benefit from superior low-level output control that exceeds industry standards.

- No maintenance

- No moving parts

- Ultra-low CO

- No generation of NOx

- Available in all stainless steel housing

- Available in Natural Gas and Propane versions

- Simple installation, with universal mounting brackets

- Durable welded steel construction

- Field selectable voltage

- Low power consumption after start-up

- TITAN Controls are UL-508A approved for UL and cUL applications

- Multiple Zoning when coupled with TITAN Controls and Gas Management System

The Versatility of Gas Catalytic IR Technology

Our innovative design not only simplifies installation and maintenance but also incorporates energy-saving features, making it an appealing option for businesses striving to minimize their carbon footprint. With numerous advantages and versatile applications, our Gas Catalytic IR technology proves highly effective in various process applications. Industries that could benefit from this technology include:

Benefits of Gas Catalytic Heating

We are proud to offer the latest in long-wave to medium-wave infrared heating technology. Our Gas Catalytic IR heaters provide a unique and powerful solution for customers looking for better control over their heating systems. Adopting Gas Catalytic IR technology into your production process will:

reduction in cure time

reduction in overall costs

or more reduction in footprint

Ask us about our free testing service!

We offer a free parts testing service at our plant in Bristol, Connecticut. You may schedule an appointment in person or mail your parts to us and we will return them for your inspection.