The latest in Powder

Coating technology

Years in the Industry

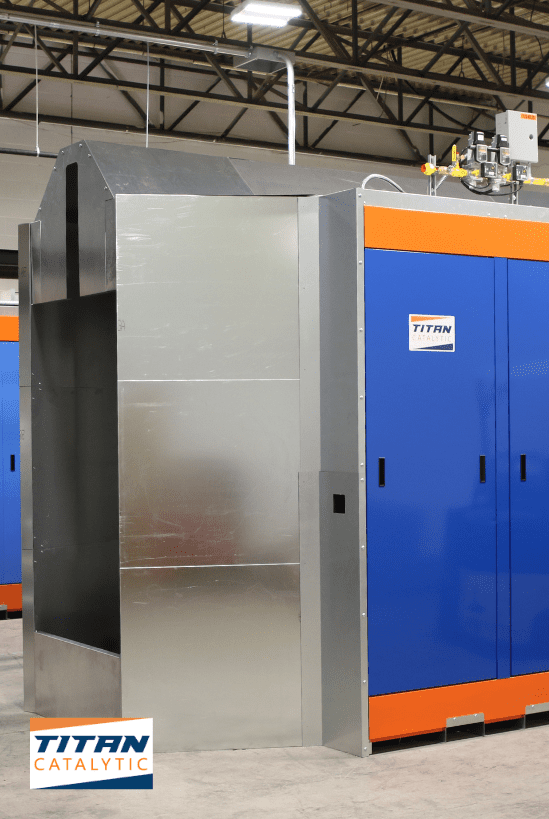

Top of the line Powder Coating Ovens

Catalytic Infrared Heaters & Ovens

At TITAN, we harness cutting-edge long-wave to medium-wave infrared heating technology to guarantee unparalleled uniformity, turndown capability, and reliability, setting the standard in heater performance. Reach out to us today, and our team will evaluate your production process, crafting a tailored, cost-effective solution to optimize your operations.

Faster Curing Times

Adopting Gas Catalytic IR technology into your production process can save up to 66% in curing time.

Cheaper Operations & Energy Costs

Switching your fuel from Electric IR to Gas Catalytic IR can reduce the Kilowatt cost to 2-3 cents/ KW and save up to 50% in overall costs.

Reduce Emissions

Implementing our Gas Catalytic Systems can reduce your environmental impact by 45% or more!

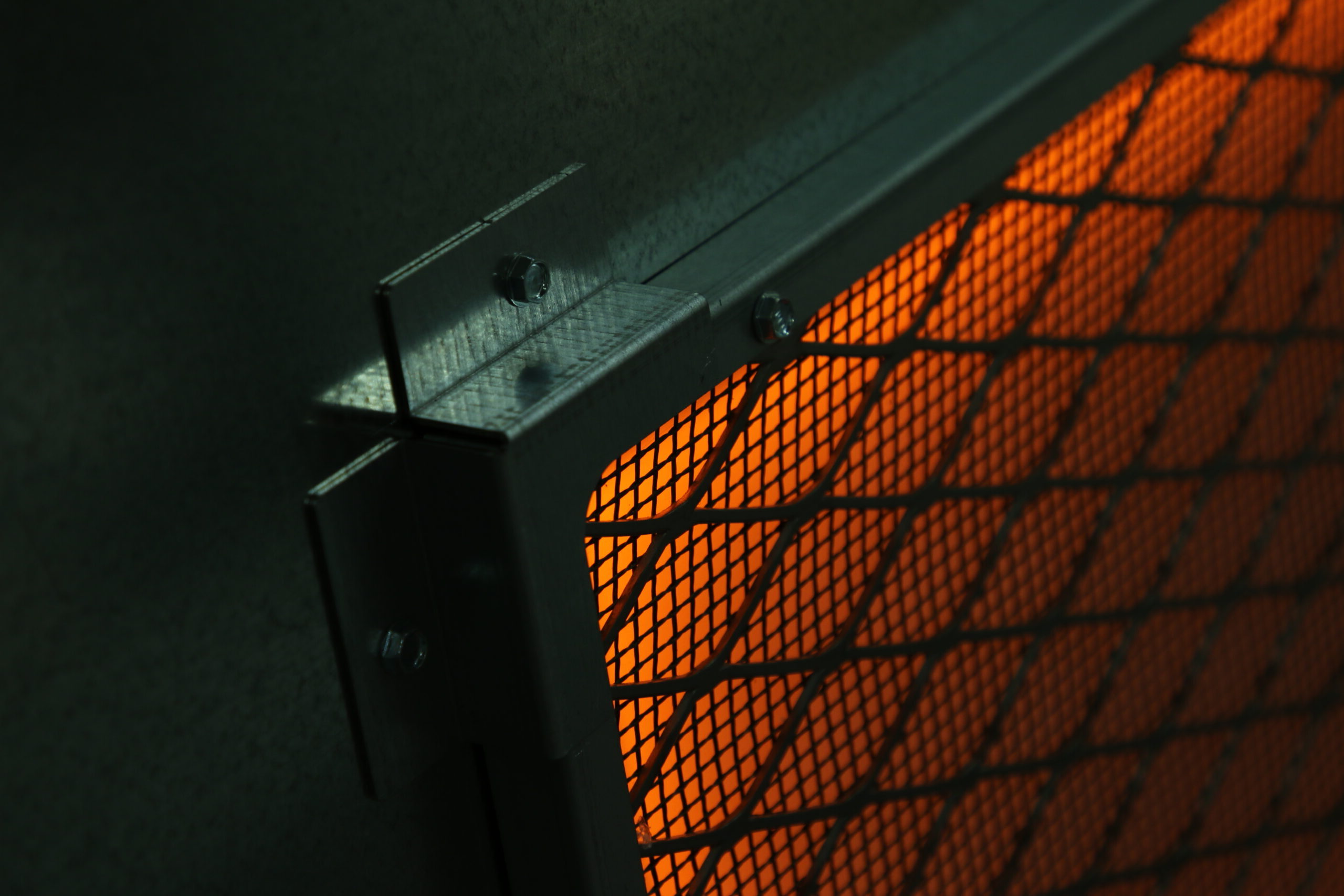

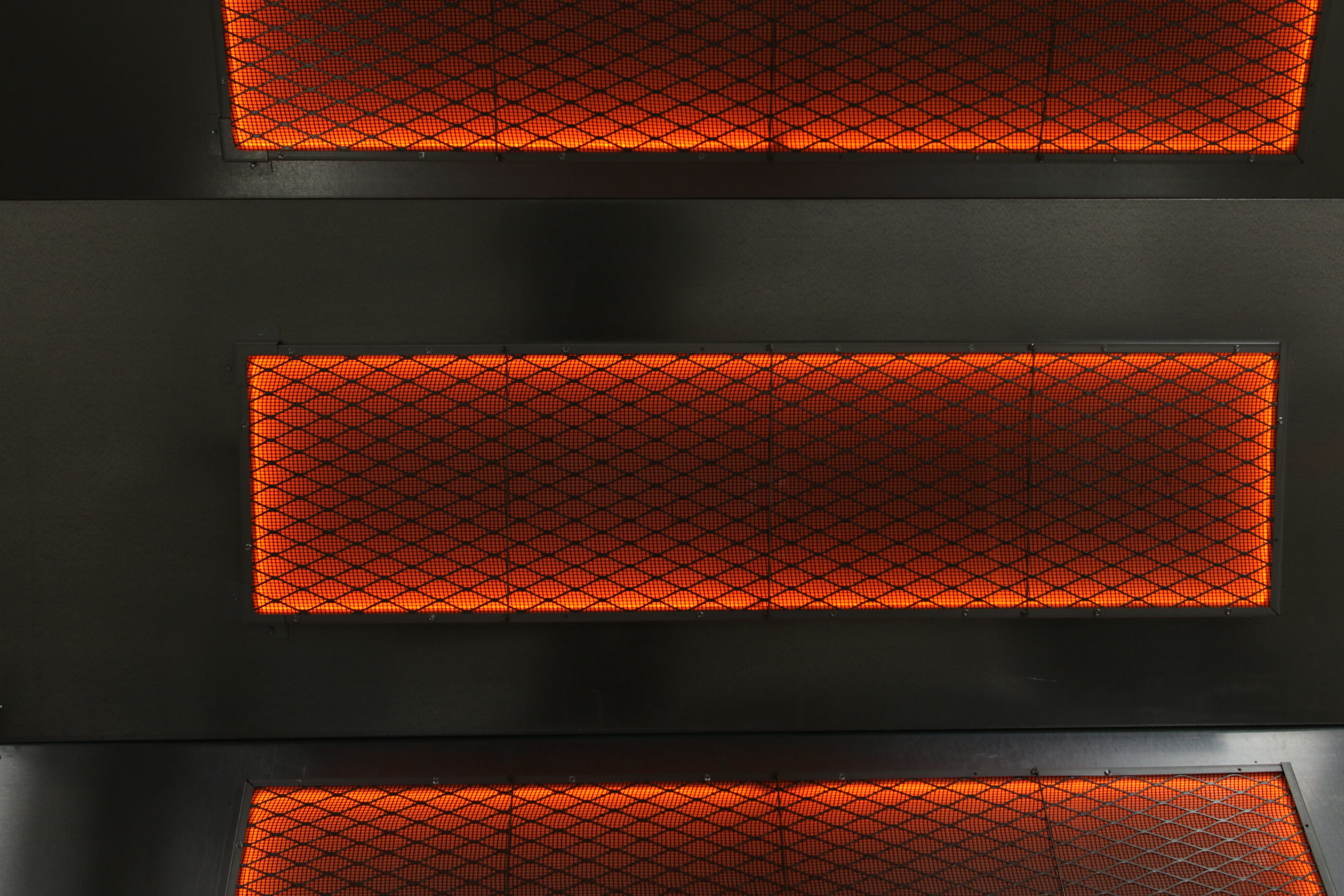

Catalytic IR Heating Technology

Safe heating without an external spark or flame

Upgrade your production line with a TITAN-Catalytic IR oven

TITAN-Catalytic’s heating technology is engineered to deliver superior performance in both high heat output and precise control. Its capacity to generate low and consistent heat levels ensures uniform distribution for curing heat-sensitive substrates. By enabling the introduction of natural gas or LP, it initiates a chemical reaction that releases the gas’s BTU value without necessitating a flame. This versatility makes it an ideal choice for various applications, including Paint & Powder Coating processes.

All of our products are proudly crafted in America and integrate Ultra-Low Emissions technology, further attesting to their environmental responsibility and quality.

Benefits of Gas Catalytic Heating

reduction in cure time

reduction in overall costs

or more, reduction in footprint

Explore Products

Heaters, Ovens and Refurbishments

TITAN Catalytic manufactures top-tier heaters and ovens designed to save our clients both time and money. Alongside of our products, we offer refurbishment services, including the replacement of platinum catalytic pads and preheat elements for TITAN heaters and other manufacturers.

Ready to give your production line a makeover?

NIKO Overhead Conveyor Systems

NIKO Conveyors equipment revolutionizes material handling by delivering unparalleled efficiency and flexibility to your production processes. NIKO solutions are customized to be sustainable low-maintenance systems that optimize production lines, enhancing quality, and boosting financial returns.

Streamline your curing systems with an overhead conveyor solution

- Powder & Paint Finishing Lines

- Paper & Textile Industry

- Thermoforming Applications

- Dehydrated Foods & Organics

- Many Other Products & Processes